In the automotive industry, wire harnesses are the unsung heroes - complex, critical, and increasingly challenging to manage. For decades, LEONI has mastered the art of adapting to a multitude of customer-specific tools, formats, and processes. Now, the company is taking a bold step forward: transforming this complexity into a standardized, digitalized, and scalable process.

Together with Siemens, LEONI is developing a unified Design-to-Manufacturing (D2M) toolchain that connects engineering, costing, and product industrialization in one seamless digital flow. The result? Higher quality, faster time-to-market, and significant cost savings.

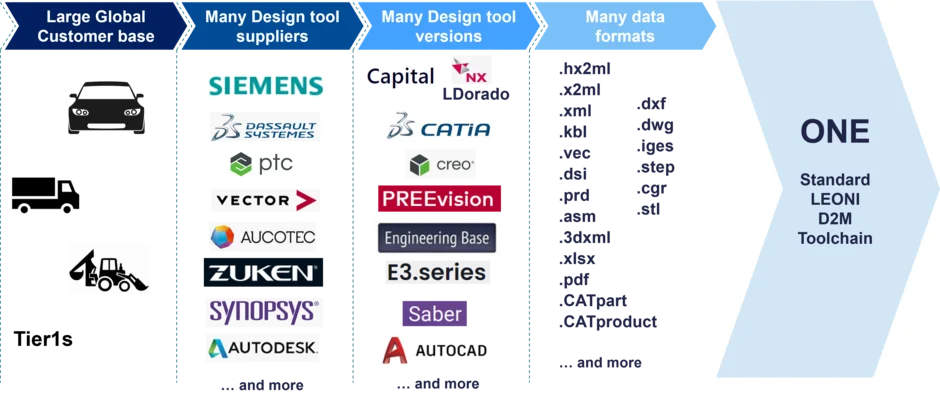

The starting point: A fragmented landscape - Non-standardized OEM designs

LEONI’s global customer base includes nearly every major OEM, each with its own preferred design tools and data formats - from PTC and Zuken to Vector, NX and CATIA (see Graphic 1). This diversity led to a proliferation of internal systems, duplicated efforts, and inconsistent data quality. “We’ve been adapting to our customers for decades,” says Sven Neeser, Head of Development Excellence. “But that flexibility came at the cost of efficiency. It was time to standardize.”

The vision: A cohesive and agile toolchain

At the core of the initiative is a clear vision to define and implement a unified and agile toolchain that enables the areas of design, costing, and manufacturing to focus on quality, time, and costs - thereby supporting LEONI’s Best-in-Class initiatives.

LEONI’s D2M initiative is built on two core principles:

- Cohesive: Connecting all disciplines - design, costing, and product industrialization - through a unified data backbone.

- Agile: Enabling simultaneous engineering to reduce lead times and improve responsiveness.

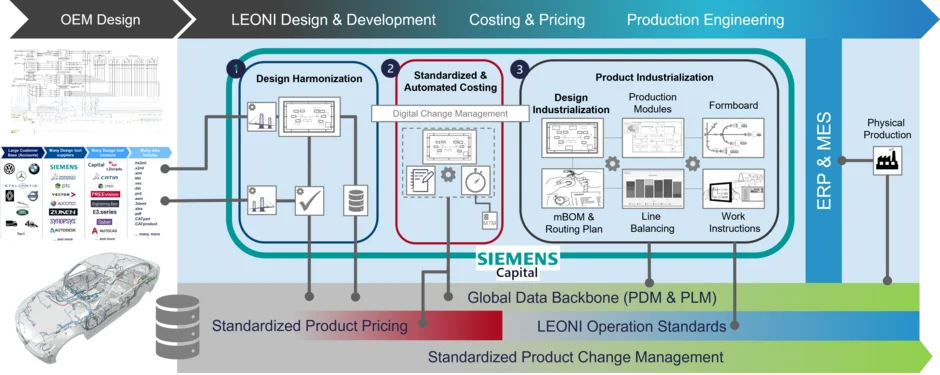

At the heart of this transformation is Siemens Capital, a comprehensive software suite that supports everything from schematic product design to automated costing and industrialization. The goal is to harmonize design, costing, and manufacturing processes to increase efficiency, quality, and scalability.

The standardization process

Step 1: Design Harmonization

The first step in the D2M journey (see Graphic 2, item 1) is to harmonize the diverse design inputs received from customers. Regardless of the original format, LEONI converts all data into a standardized model-based product design. This ensures consistency, enables automation, and lays the foundation for downstream processes. This approach is essential. Due to their complexity and variant diversity, wiring harnesses require a consistent end-to-end data foundation to enable automation and scalability.

Key benefits include:

- Automated design rule checks

- Visual and data-based validation

- Seamless integration with LEONI’s parts database (LEOparts)

Step 2: Standardized & Automated Costing with precision

Costing remains largely a manual or, at best, semi-automated process - often tailored to individual accounts and reliant on varying data quality. To address this, LEONI initially introduced a centralized calculation and pricing tool capable of processing diverse design data inputs. This tool validates calculation parameters and generates sales quotations. It is integrated with key central data sources, including project data (Salesforce), purchasing costs, a central time/process database, and a central component database.

The result? Greater automation, improved traceability, repeatability, simplified tasks, enhanced data accuracy, and significant time savings. While this provides a solid foundation, it still relies on design data from multiple, unaligned sources - limiting its full potential. “This is where Siemens Capital adds real value”, says Phil Clarke, Head of Global Sales Support.

With standardized, high-quality design data and consistent data sources - alongside a centralized Methods-Time-Measurement (MTM)-based operations database - LEONI can now generate accurate cost estimates in minutes (see Graphic 2, item 2). This advancement enables the use of standardized operations and corresponding time allocations, allowing for the automated creation of bills of materials (BOMs) and labor time estimates directly from design data.

“Costing and pricing are now clearly separated”, explains Sven Neeser. “We understand our true costs better - and that’s the foundation for better pricing decisions.”

This shift enables:

- Accurate, consistent and transparent cost structures

- Reduced reliance on tribal knowledge

- Improved internal benchmarking and pricing strategies

Step 3: Product Industrialization for manufacturing

Once the design is validated and costed, it’s time to hand it over to production (see Graphic 2, item 3). This involves breaking down the harness into modular production units, distributing tasks to workstations, and generating workplace-specific work instructions. Siemens Capital provides a platform for integrating and automatically applying internal expertise, e.g. by creating proposals for production modules or ergonomic formboard layouts, which are then validated by experts. This reduces manual effort and supports LEONI’s global manufacturing operations by simplifying complex harnesses into manageable units.

Highlights include:

- Automated generation of proposals for production modules

- Optimized formboard representation for operator guidance

- Integration with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES)

Product modularization is especially important given LEONI’s global manufacturing footprint with over 87,000 employees, many performing manual tasks. Standardized and repetitive work packages enable faster onboarding of new employees, reduce error rates, and ensure consistent production quality. “Operators are only as good as the instructions they receive,” says Cyril Gentelet, Operations Project Manager.

Another potential feature, currently in the evaluation phase, is Capital Line Balancer, a tool for optimizing workstation content to avoid bottlenecks and waiting times in assembly line concepts.

Standardized Product Change Management - Managing change at scale

The implementation of a unique and global closed-loop change management system addresses the high volume of engineering change notices - approximately 20,000 annually at LEONI. Change requests are now recorded, cost-assessed, and synchronized across design, costing, and manufacturing departments with minimal manual intervention, ensuring rapid and consistent updates throughout the value chain. “This is the holy grail,” says Neeser. “We can now trace every change from customer request to shop floor execution - without losing data or time.”

Lessons Learned: It’s a people journey

While technology is powerful, the biggest challenge has been our legacy. Standardization requires a mindset shift - from local optimization to global alignment: long-established habits must be broken, resistance overcome, and global teams aligned to common processes. LEONI employs transparent communication, internal marketing, and a phased rollout strategy. Clear role definitions and a cultural shift toward openness and accountability are essential to align global teams with new processes. A foundational element of the initiative is the establishment of a 'Single Source of Truth' for data. This unified data foundation supports automation, the reuse of intellectual property, and improved compliance and transparency.

Key lessons include:

- Start with mindset: Prepare teams early and involve leadership

- Define clear scope and responsibilities (RASCI)

- Clean and enrich legacy data before migration

- Deploy in phases—don’t wait for the perfect blueprint

The Payoff: Tangible and transformational

Quantifiable benefits of the initiative include:

- 20–30% increase in utilization of indirect resources

- tenfold reduction in customer-specific documentation

- fivefold decrease in IT infrastructure (e.g. Excel-Macros)

These are complemented by intangible gains such as the consistent capture and application of intellectual property (IP) and improved traceability. And perhaps most importantly, a scalable foundation for future innovation - including AI-driven design, predictive costing, and smart manufacturing.

What’s next: A long-term commitment

The initiative deployment is well underway. A good portion of LEONI’s automotive designs' portfolio has already been migrated to the new design standards. Full implementation will take time - but the direction is clear. “This is a multi-year journey,” says Neeser. “But with Siemens as our trusted partner and a clear roadmap defined, we’re confident that LEONI is building something truly transformative.”

Do you have a question?

We’ll be glad to help. We look forward to hearing from you.