High-performance computers may form the core of new E/E architectures, but at a lower level, zone controllers manage data traffic, energy distribution, and much more. In the future, no zonal architecture will be possible without the local intelligence provided by these controllers.

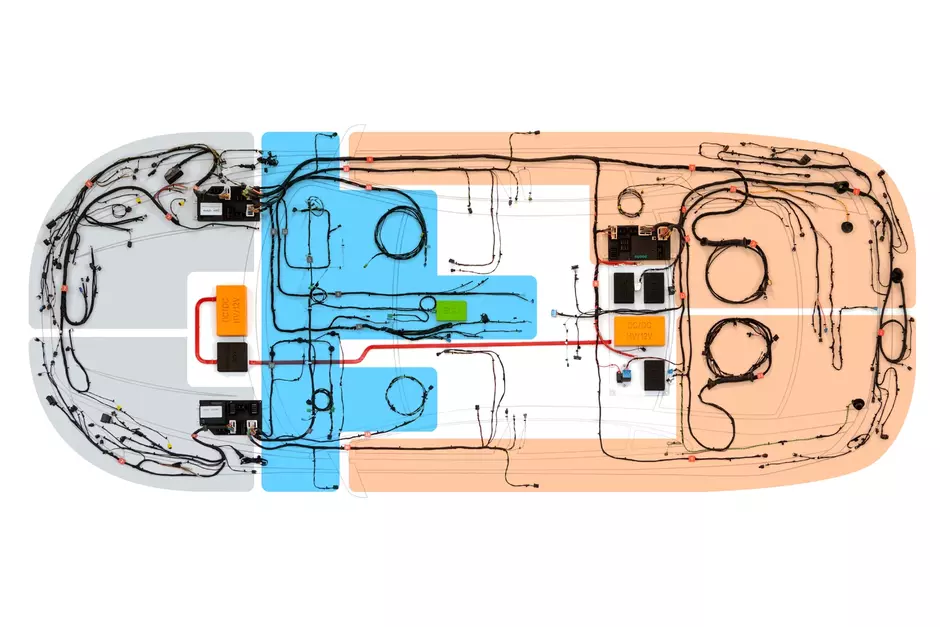

Today’s customer-specific wiring systems often have more than 100 control devices and more than 1000 individual wires, and these numbers continue to grow. Trends such as connectivity, digitalization, autonomous driving, power train electrification, and CO2 reduction are leading to ever more electronics in vehicles. The question is: how can all of this additional electronic content be integrated, given that wiring systems are already reaching the limits of complexity and manufacturing?

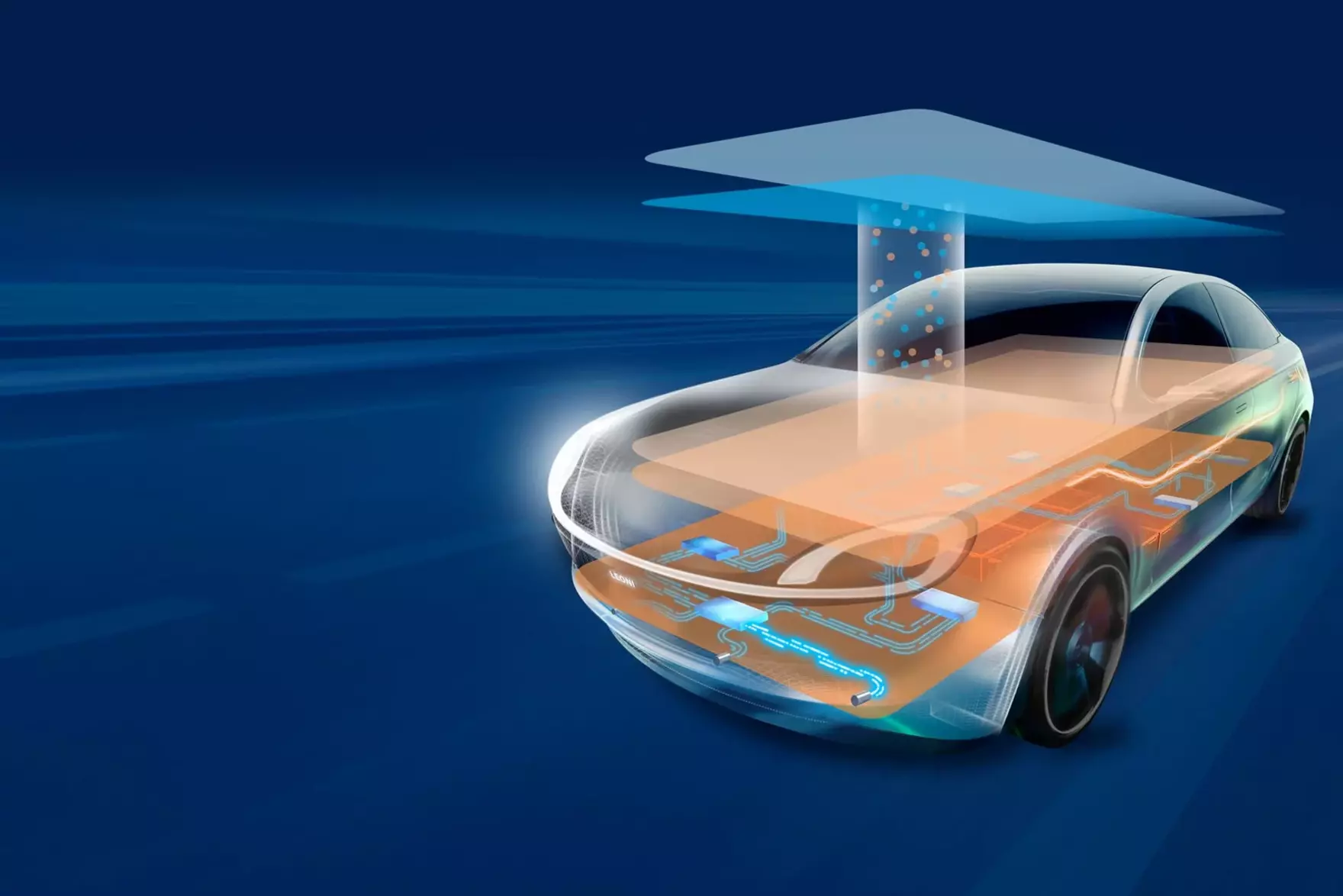

The magic word here is “simplification.” We are moving towards zonal architecture, an approach that breaks down the impenetrable mass of “cable spaghetti” into manageable portions. Put briefly, future wiring systems will have fewer and more powerful central computers, connected through high-speed data highways. Around the high-performance computers, the wiring system is subdivided into multiple zones. Within these zones, a zone controller independently performs subtasks such as power distribution or data management from and to the sensors and actuators. Zonal architectures of this type will go into serial production within the next two years. LEONI has already received its first customer orders for these architectures.

Why are zonal architectures better? They are clearly structured and have defined interfaces. They consist of fewer, but significantly more powerful processors and cables. The cable harnesses for individual zones are much smaller and simpler in design, making them more amenable to (partially) automated production. The gradual increase in automation improves production quality and depth of documentation for the wiring systems.

Zone controllers are the worker bees of the wiring system

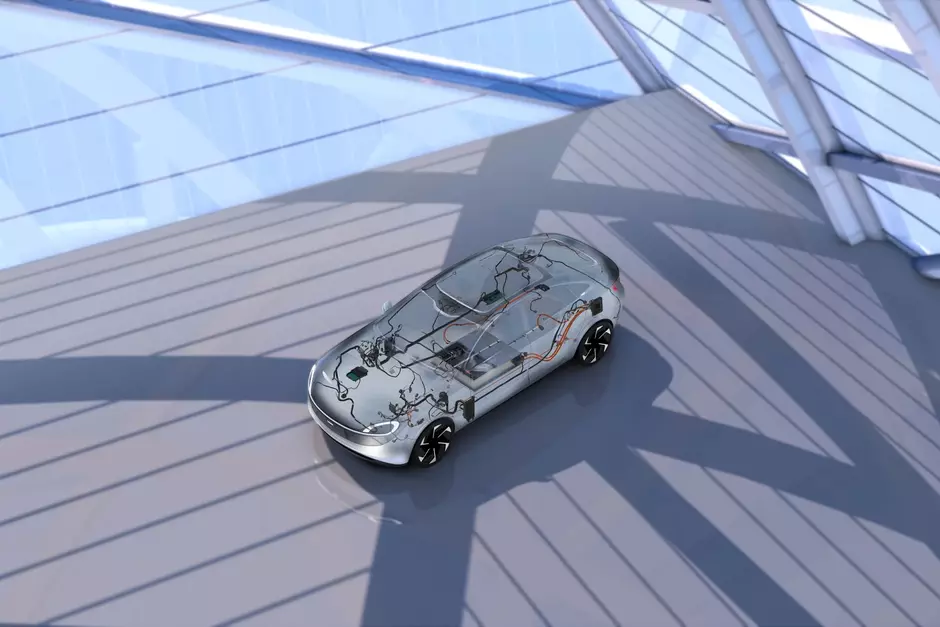

One key element in zonal architectures is the zone controller. As a mid-level function, the zone controller is the interface between software-based functionalities and the vehicle's physical environment. As such, it is an indispensable foundation for the software-defined vehicle (SDV) of tomorrow. Zonal approaches currently have only a few zone controllers, but we are convinced that this number will gradually grow to a low double-digit figure.

LEONI has collaborated with Valeo to develop the first generation of zone controllers, and has already acquired the Renault Group as its first customer for serial production. In the collaboration with Valeo, we are responsible for developing intelligent power distribution and for the use of modular connectors, with a focus on the integration of different signal and power contacts. In this process, we are already taking the automated production of zonal (sub-)cable harnesses into account. We are therefore responsible for ensuring a failsafe power supply for the zone controller, an essential requirement for autonomous driving functions. We are also designing the zone controller’s thermal management, as well as its space-saving package and integration at the vehicle level. Valeo bears overall responsibility for the project and development of the microcontroller and gateway portion, and also handles production.

Greater performance flexibility instead of off-the-rack solutions

According to our estimates, 20 to 95 percent of all vehicle functions will be routed through the zone controllers in the future. This means that depending upon the vehicle's class, equipment, and E/E architecture, a zone controller will have to perform a variety of tasks and meet different requirements. We have taken this complexity into account with a modular and scalable design of the zone controller layout. Thanks to our many years of expertise in wiring systems, we can adapt a zone controller's hardware and software to each specific application.

For example, ethernet data cables are currently the preferred means for routing the massive quantity of raw data generated by camera, lidar, and 3D radar sensors to the high-performance computers. This method is expensive, and also increases the time and costs involved in the production of the wiring system. One solution could be to use separate data cables from the sensors to the zone controllers, at which point all sensor data can be bundled and forwarded to the high-performance computers. This should be feasible for lidar and 3D radar sensors, since their data can be compressed without loss and routed to the high-performance computers practically in real time through ethernet lines with 1.5 Gbit/s bandwidth. Camera data cannot be so easily compressed, however. If there are multiple cameras per zone controller, this would require more expensive 10 Gbit/s ethernet cable and costly chip technologies in the zone controllers. Here, the OEMs should work with the wiring system specialists to define a strategy for consistent data routing.

New solutions are also needed for power distribution. Electric drives or actuators for driving dynamics applications have higher power requirements. In current systems, they are usually fused centrally with a separate pre-fuse box. Zone controllers with “intelligent” electronic fuses could offer benefits such as greater freedom in power distribution and in the vehicle package. Another option worth considering is to increase the (sub-harness) voltage to 48 V in order to provide sufficient power and optimal fuse protection.

Intelligence through a combination of software and high-performance hardware

Other potential areas for optimization can be found in the numerous interfaces and small (sub-)networks, and in the bypasses for performance-critical data routing that continue to exist in the initial zonal architectures. In a strict approach, all bypasses and subnetworks would be eliminated, and data traffic would be consistently routed through the zone controllers. This requires redesigned microcontrollers and software layers, as well as significantly faster interfaces. Such interface technologies can be adopted from IT server technology, but they are not very economical. We assume, however, that in addition to a holistic automotive architecture, a consistently designed routing approach will be more cost-effective, and above all less complex.

LEONI has identified a few adjustments that can made to mitigate the conflict between the goals of more powerful and simpler E/E architectures on the one hand and costs on the other. Flexible zone controllers that can adapt to a given application’s architectural and power requirements are essential to such efforts.

Do you have a question?

We’ll be glad to help. We look forward to hearing from you.

Dr Frédéric Holzmann

Head of EE Architecture & Product Innovation