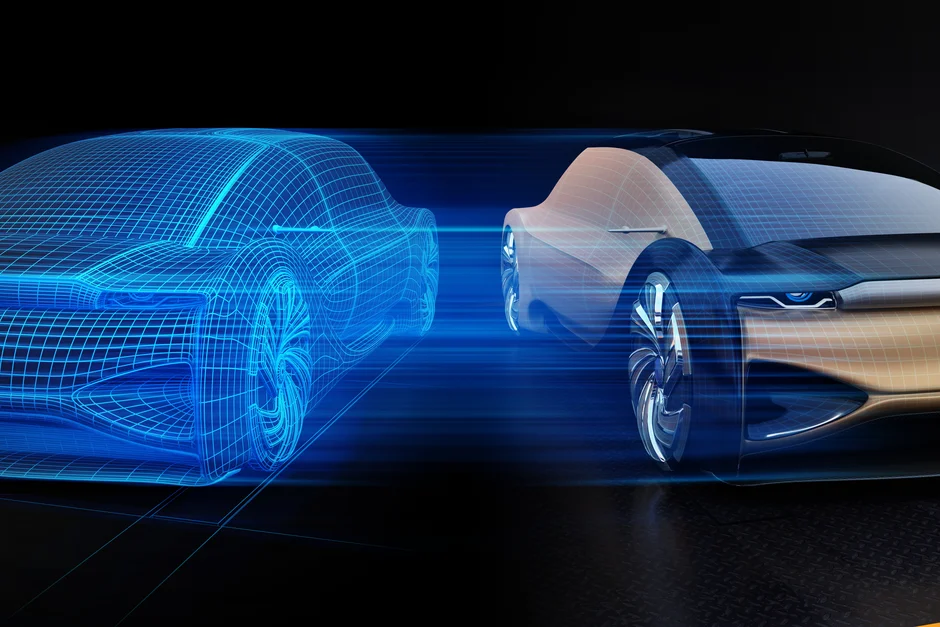

Simulation

Identifying better designs faster

We use various commercial software applications and inhouse solutions to provide our development departments and customers with reliable suggestions from the initial design phases. The advantage for LEONI and our customers: optimized development times with reduced need for physical tests.

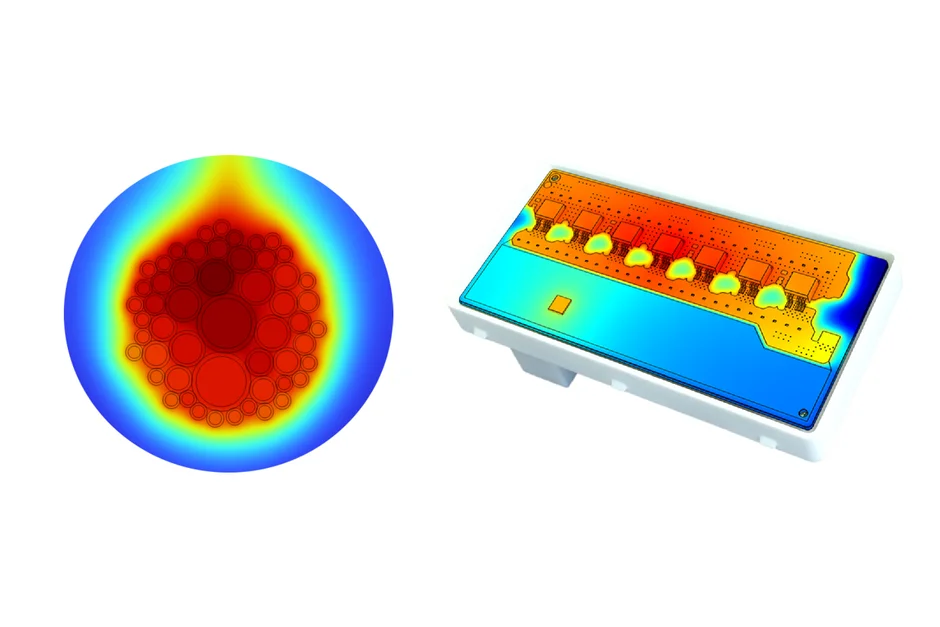

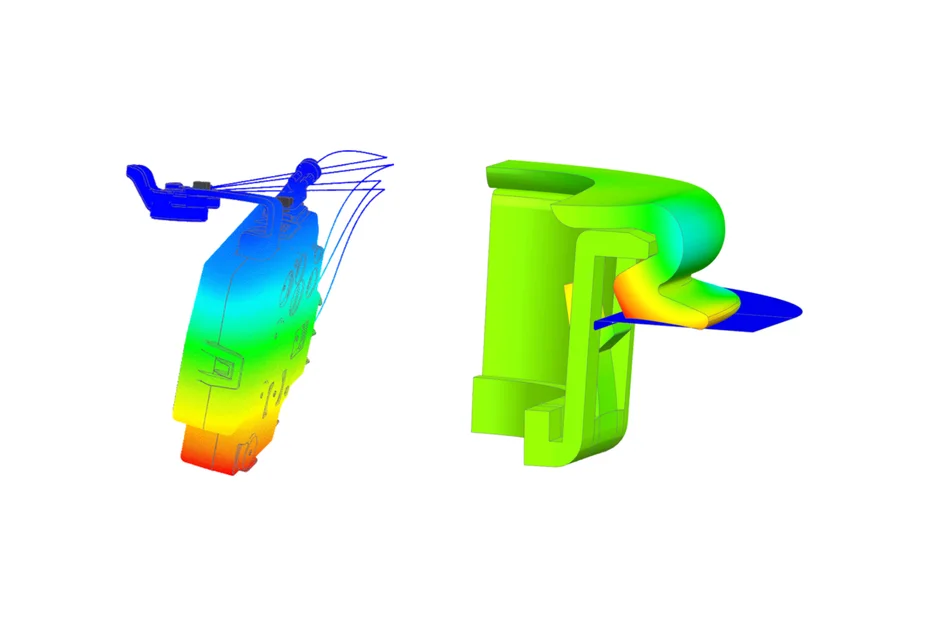

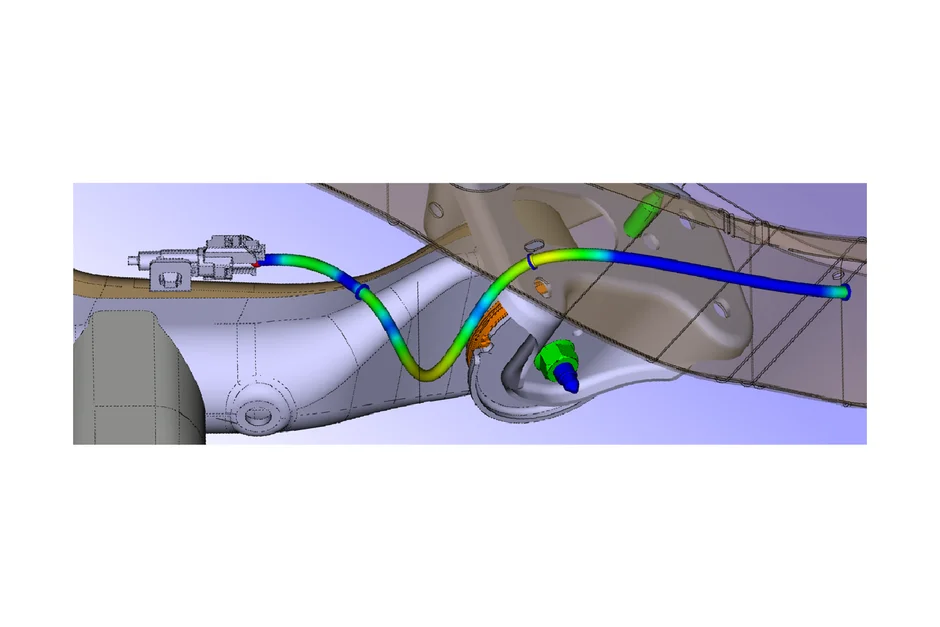

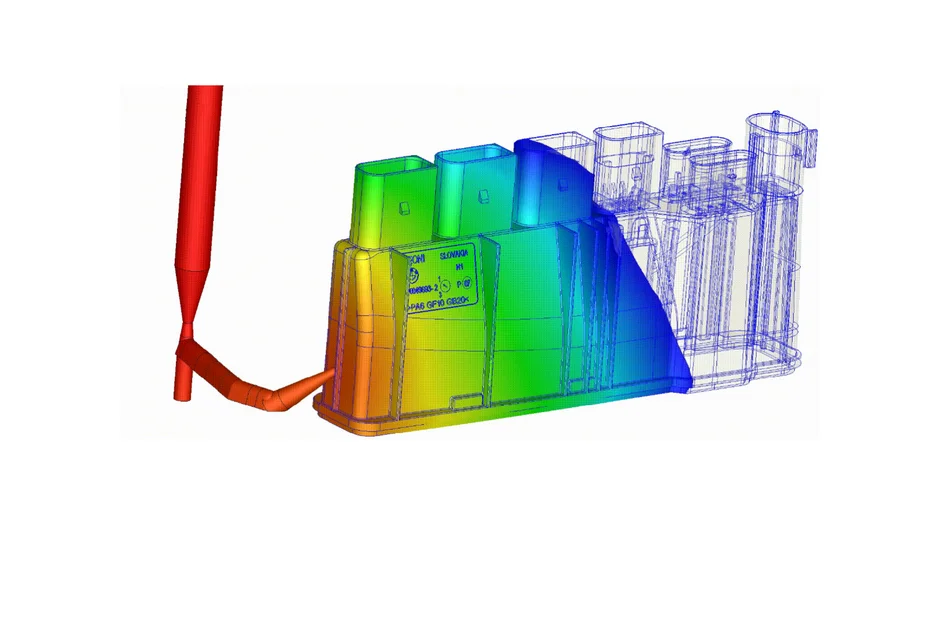

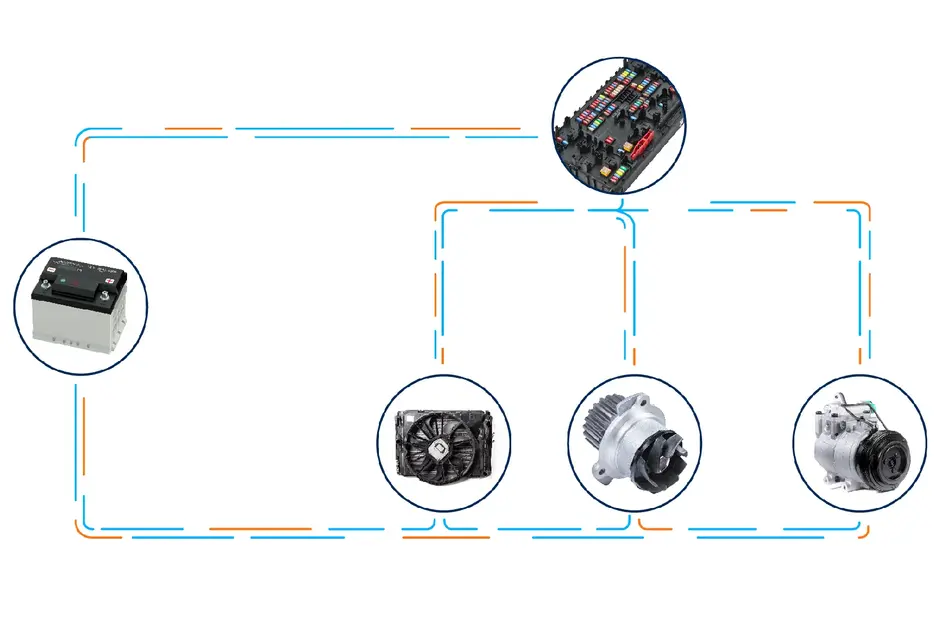

Comprehensive possibilities & methods

LEONI’s interdisciplinary simulation includes the ability to simulate a wide range of materials and components. This includes electro-thermal effects, 3D cable routing, evaluation of dynamic loops and the effects of a variety of mechanical and vibration influences, to ensure optimal wire dimensioning and reliable and robust component design.

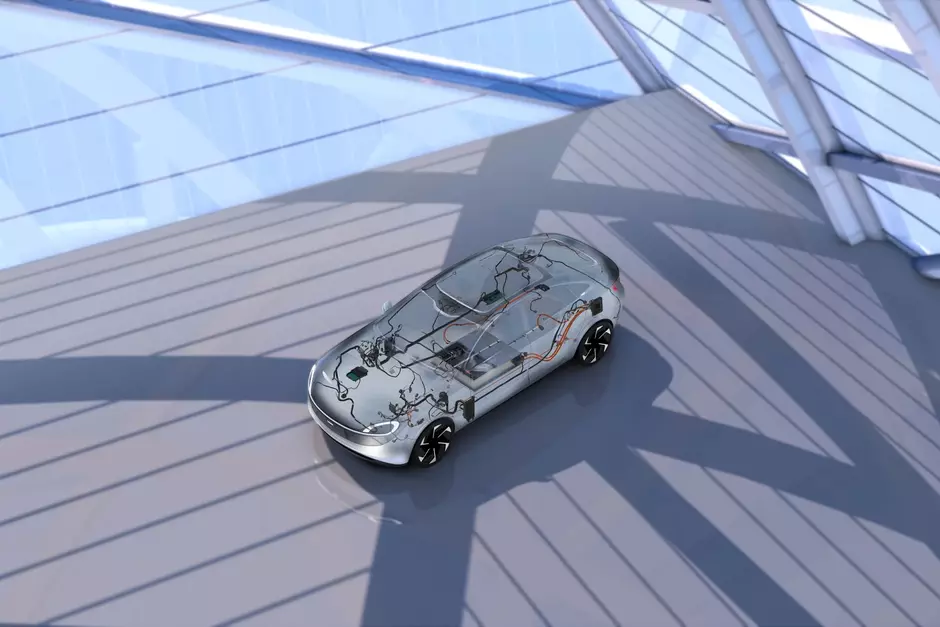

With digital functional simulation, LEONI is able to identify optimal future architectures of wiring systems and stable power nets. Supported by numerical methods, Simulation provides the technical health care of our development departments for optimized, reliable and robust cable harness and component design.