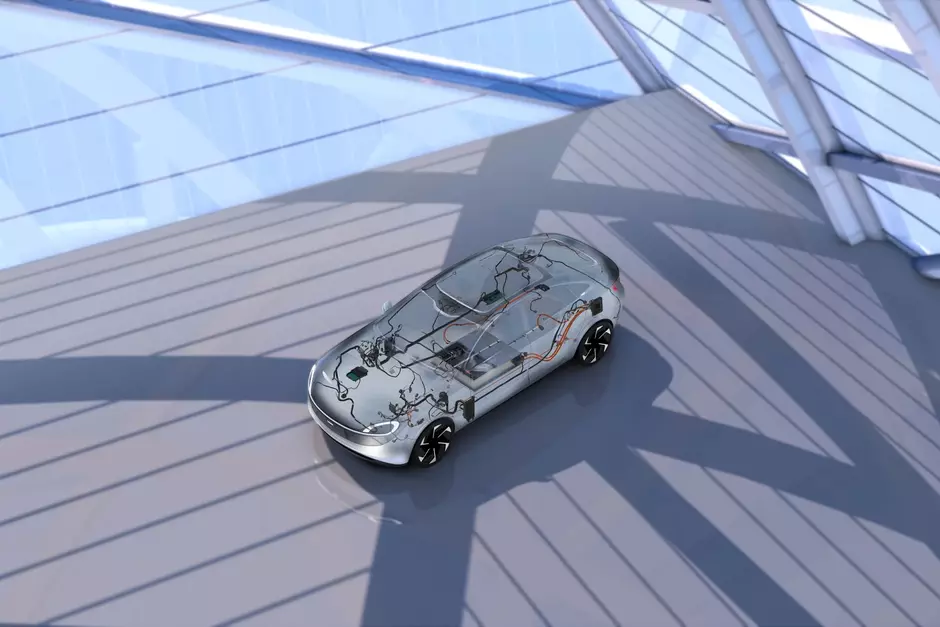

Prototype construction, including rapid prototyping, plays an important role in the development of vehicle components and therefore also of wiring system components. Even in the earliest concept and pre-development phase, engineers have to test designs and, in some cases, functionality. Prototypes must be built as product samples for this purpose.

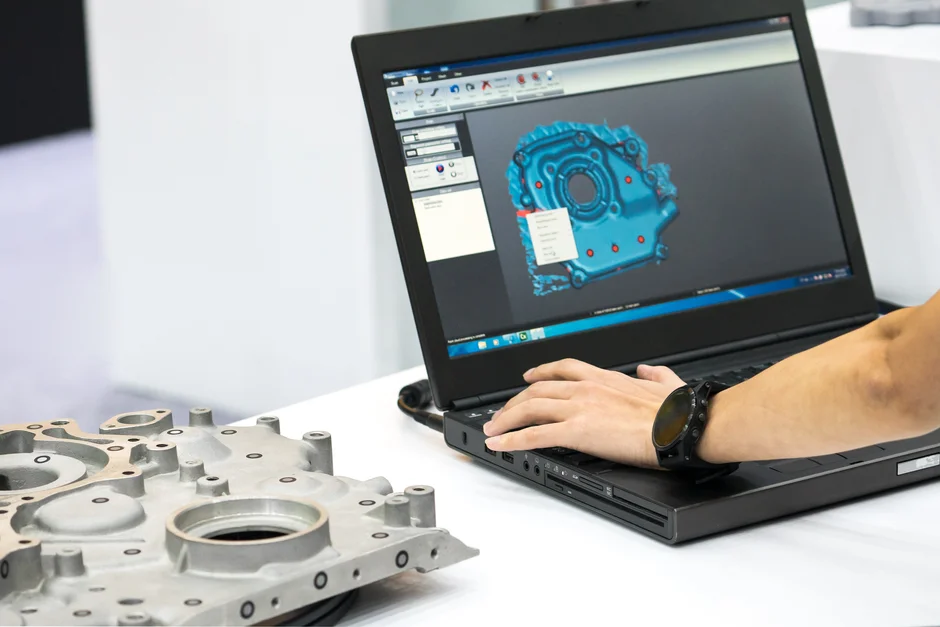

Fast and cost-effective methods of prototype construction are required in order to meet the increasingly tight development cycles. The construction of tools as well as the mechanical processing of various materials and the use of generative processes are common technologies and processes in the product development cycle.

Through continuous further development, rapid prototyping enables the construction of functional prototypes that can already withstand certain stresses and allow functional tests and design verification.

Our competencies and services:

- Coordination and Interface for Prototyping of components and new products

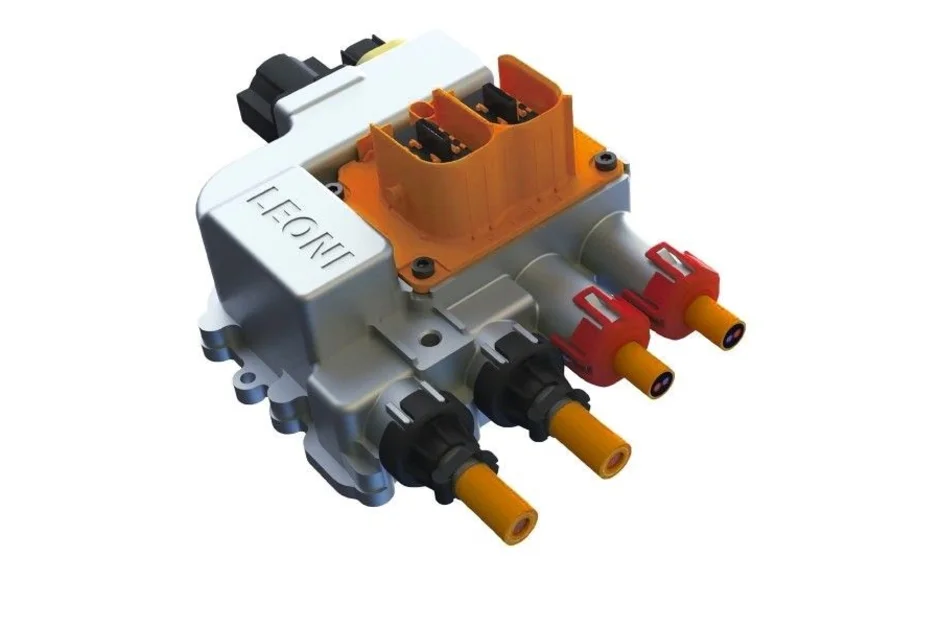

- Intelligent use of all common and new technologies and processes to build up both design but also functional prototype samples as Rapid prototyping and Rapid Tooling (3D-printing, Selective Laser Sintering SLS, CNC-milling) for example

- Development and set-up of Test- and Assembly Equipment (Devices for vibration, sealing, mechanical tests and other test equipment)

- Building of Prototype Components & Harnesses (HV- boxes, Demonstrators, Harnesses)