Roth/Stuttgart, 22 May 2023 – Rapid development work without quality deficits: Leoni will present its comprehensive range of cables and solutions for electromobility at „The Battery Show Europe“ from 23 to 25 May in Stuttgart. In Hall 8, Booth A-74 the division Automotive Cable Solutions (ACS) will draw attention to the significance of simulation processes.

Whereas in cable development it was previously necessary to approach the optimal design of a cable for the defined application by means of sample production and lengthy series of measurements, today development cycles can be significantly reduced by means of simulation, analysis and test procedures. Leoni Automotive Cable Solutions is presenting how at the trade fair.

Simulation using the example of cables for electromobility

People pay particular attention to electric range when buying an electric vehicle. Especially short charging times are desirable particularly for long journeys - yet these do not depend just on the vehicle and the battery fitted in it, but also on the available charging infrastructure. However, the transferred current causes the whole charging loom to heat up. For this reason, thermal management is playing an ever more important role.

All charging loom components, from the charging infrastructure through to high-voltage cables in the vehicle, require extensive testing of their thermal behaviour and their interactions with adjacent components such as connectors or contact elements. Leoni meets the sometimes rapidly mounting requirements placed on the current carrying capacity of its products with a hybrid approach comprising computer-supported simulation development and realistic, metrologically recorded testing.

Frequently, for example, charging cables are developed bespoke to customer requirements. Making these prototypes is a time and cost-intensive process, which is why thermal properties are considered as early as at the design stage where possible. For this reason, cable designs are compared in advance using simulation tools to identify especially suitable designs.

Beyond previous limits

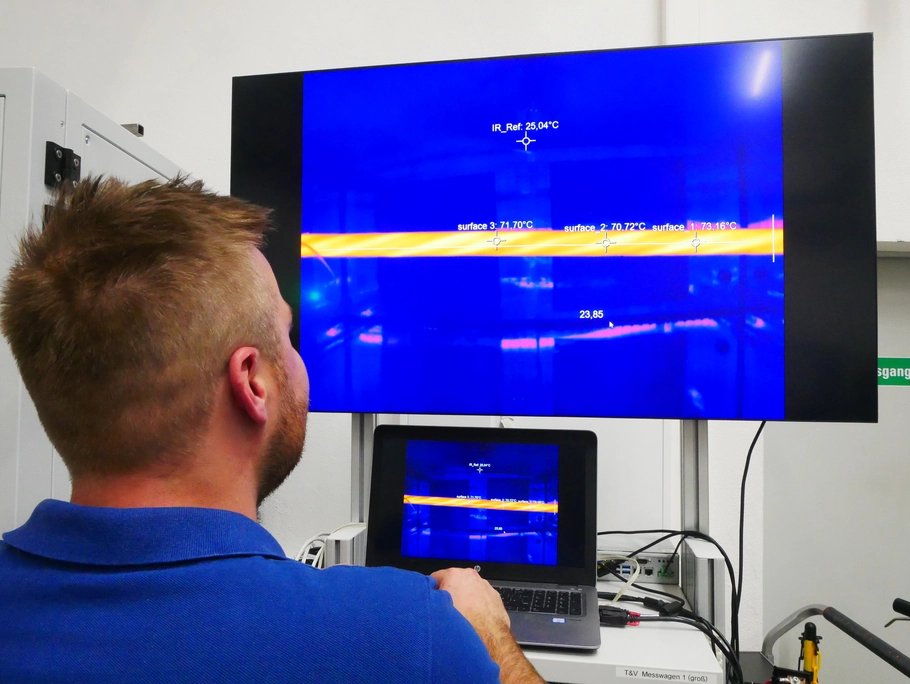

Subsequently manufactured prototypes are subjected to an in-depth examination under realistic conditions in the ACS test lab set up for this purpose. This involves all influences being acquired and recorded using precision measurement technology, thereby allowing the stationary and transient behaviour of the charging cables and other components to be precisely analysed and reconciled with the simulation results. The acquired data makes it possible, for example, to evaluate a thermal ‘sweet spot’ that provides the customer with important information for design of the required cooling unit.

Leoni is confronting the market’s increasing agility with this strategy and accelerating its own product development by reducing development times and the number of prototypes. Yet developing straightforward product models will not be the limit of our simulation expertise. In the medium term, we also intend to map such adjacent components as connectors and inlets by means of thermal networks and to combine these with cabling models into complex system simulations.

Temperature recording in the Leoni ACS test laboratory.

Press contact

Gregor le Claire

Corporate Press Officer

Claudia Schertel

Marketing LEONI Kabel GmbH